AI was used in the development of the curriculum for the ‘Digital manufacturing’ course. Read these experiences here, both the process and the result, which can also be interesting for other Fablabs when using AI such as Copilot.

Shafier Abdoelaziz, Pieter van der Hijden, Räquel Zeegelaar

We used AI for the ‘Digital manufacturing’ course for the ‘Digital manufacturing’ course in Suriname. Our experiences, both the process and the result, can also be interesting for other Fablabs. This memorandum is written in Dutch; The AI Prompts and the results are idem; The export products: Word file, online mindmap and website are that too. The export products are online:

• PDF document (https://zaplab.villazapakara.com/df-handouts/pdf-viewer.html?url=handouts-Digitaal–babrice.pdf)

• Online mindmap (https://zaplab.villazapakara.com/df-handouts/mindmap.html)

• Website (https://zaplab.villazapakara.com/df-handouts/index.html)

1. Background

Zaplab at Villa Zapakara (Suriname) has set up a “Digital manufacture” course for young people and young adults in the interior of Suriname with secondary education education level with the help of Canadian Leaf. The course pays attention, among other things, to the development of digital skills. With the help of digital manufacturing techniques such as 3D printing, CNC mills, digital embroidery and laser cutting, traditional crafts (carvings, pangi embroidery) are integrated with these techniques to stimulate possible innovations and employment. For each of these techniques we have a workstation consisting of a laptop, a manufacturing machine, associated hand tools, materials, instructions, spare parts, PPE. These workstations are available during the course meetings, but also interim and afterwards.

The course consists of ten one -day workshops on location, just as many online guidance meetings and permanent local facilities (space, workstations, guidance). At the end of the course, the participants carry out a final project in small groups that is presented at a closing exhibition.

The course covers a period of ten months and started in March 2025 in Klaaskreek (Brokopondo) and Moengo (Marowijne); The exhibitions are provided for December 2025. The number of participants in both locations is around 25.

2. Curriculum development

The development of the curriculum started with formulating seven continuous learning lines that would, together would cover the intended objectives (also agreements with the sponsor). We have worked out these continuous learning lines in a competence framework of seven domains, five developmental stages per domain and three competencies (knowledge, experience, attitude) per stage. All in all, so 7*5*3 = 105 competencies.

We then set up a program for ten one -day practical workshops. These workshops have a fixed timetable with parts of 30 and 45 minutes that are given either plenary or in two or four groups. The latter is done both to actively involve the participants in the program and to make optimum use of the available workstations. There are always four trainers available.

Within the program, the trainers give assignments to the participants. The participants can use a collection of hand-outs, a reference work that is also beneficial outside the course. The developers, certainly together, had enough ready knowledge to prepare these hand-outs themselves. But time penetrated. That is why we have experimented with the use of AI, IC Microsoft Copilot.

3. Experiment with AI

Copilot is the Artificial IntelligenceMicrosoft assistant. A user can call Copilot from Microsoft applications, such as the Internet Browser Microsoft Edge. The user type in a “prompt” (question) and Copilot responds with an answer. The user can possibly ask follow -up questions. No problem to ask the questions in Dutch; The answers are then too.

The first handout For the participant, a compact description of the four workstations should contain. We tried to have it put together by Copilot. We wrote one prompt for the 3D printing workstation. In the prompt we walked out of the sections from the Bill-of-Materials for workstations.

Prompt

We want to put together a number of hand-outs for participants in a course from our Fablab. Our participants live in the interior of Suriname. We assume a workshop with a “3D printing” workstation consisting of a laptop and a machine, IC a 3D printer, with accessories.

• Describe the function of this machine

• What are the most important components of this machine incl. Their function?

• What are the most important hand tools that belong to this workstation including their function?

• Which consumption materials do you need at this workstation?

• Which spare parts do you want to have within reach at this workstation?

• What safety risks does this workstation know? Which PPes are needed?

The result was amazing. Neat lists with lists that we didn’t have to change anything anymore.

Result

Workstation 3D printing

Function of a 3D printer

A 3D printer is a device that converts digital building plans into tangible, three-dimensional objects by building the object low after low. This process is often used for rapid prototyping, model building, and even in the medical and art sector.

Main components of a 3D printer

1. Extruder: Moves and melts the filament to build the object low by layer.

2. Print bed: the surface on which the object is built. It ensures good adhesion of the first layer and influences the accuracy and stability of the final object.

3. Nozzle: The mouthpiece that extrudes the melted filament (= comes out). The diameter of the nozzle influences the resolution (quality) and the thickness of the layers.

4. Motherboard: the control board responsible for the fundamental operations of the printer.

5. Frame: Keep all the components of the printer together and ensures stability.

Main hand tools for 3D printing

1. Scraper: for removing printed objects from the print bed.

2. Tweezers: For the handling of small parts and the removal of excess filament.

3. Needles: For cleaning the nozzle.

4. Allen key: For tightening screws and bolts.

5. Screwdriver: for general maintenance tasks.

Consumption materials for 3D printing

1. Filament: The basic material used for printing, such as PLA, ABS, PETG, and TPU.

2. Cleaning agents: such as acetone for cleaning printed objects.

3. Lubricants: for the maintenance of moving parts.

Spare parts for a 3D printer

1. Nozzles: Reserve mouthpieces for different filaments.

2. Print bed: Replacement print surfaces.

3. Extruders: Reserve extubers in case the current defect becomes.

4. Fans: For cooling the printer.

5. Thermistors: For measuring the temperature.

Safety risks and PPES

Safety risks:

1. Fire hazard: By overheating the printer.

2. Chemical: vapors of certain filaments.

3. Mechanical dangers: through moving parts of the printer.

Personal protective equipment (PPES):

1. Safety glasses: To protect the eyes against flying particles.

2. Gloves: For the use of hot parts and chemicals.

3. Dust mask: to prevent inhalation of fine particles.

4. Scaling up

We thought our experiment was successful and could apply this approach to all desired hand-outs. We wanted it before the program actually started. Guideline was an overview (table of contents) for the collection of hand-outs.

4.1. Overview

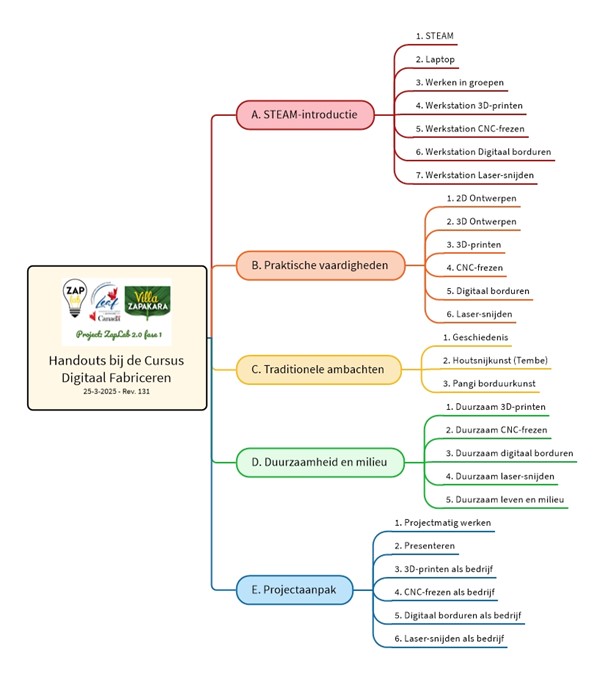

The main layout in five topics broadly follows the classification of the program.

(Text continues under the image)

Figure: Table of contents of the hand-out collection

4.2. Prompts

Through AI our work changed to writing hand-outs in writing prompts. The latter had to be done as efficiently and effectively as possible. What have we learned:

• A clear prompt is half the battle.

• Treat only one topic per prompt, for example 3D printing; Do not ignore other processes at that time.

• Build a prompt so that you only have to change a single word to create a new prompt; For example, replace 3D printing with CNC mills.

Especially the latter Bullet Point is An Time Saver. Note that our experimental prompt is about a hundred words long, while we only use the word 3D printing twice. Change that in CNC milling and your prompt for CNC milling is ready.

We used this approach for the various manufacturing processes:

• Workstation X

• X as a process

• Sustainable X

• X as a company

Four completely different template prompts that could apply to various digital manufacturing processes by filling in a single word. We also applied the same approach to the handouts for: 2D designs with inkscape and 3D designs with Tinkercad.

4.3. Results

The results that Copilot produced were immediately usable in almost all cases.

Only with the hand-out about traditional crafts did it go wrong. The texts were too general for us and therefore added too little. We then formulated a new promptly that only related to one craft (wood carving) and then also applied to the other craft (embroidery art). These texts were agreement with the element “History”. We have adjusted the latter manually.

5. Publish

5.1. Word document

A collection of 26 Copilot results is not yet a whole. It still cost us some “gymnastics” to make a net formatted in it. That should be easier, but that requires further investigation.

5.2. Trunk copy

Because mind manager offers attractive opportunities for publication, we have imported the Word file into mind manager and stored as a .mmap file. For the time being we use this MindManager file as our tribal copy. The advantage of this is that you can easily publish updates from MindManager as a Word file (and then PDF), as an online interactive mindmap and as a website. The disadvantage, however, is that the developer must then have a license from the commercial product MindManager. If the publications such as online mindmap and/or website are not required (longer), the Word file can serve as a tribal copy.

6. Finally

We are very satisfied with the result that we have achieved work for each other in no more than one day. Yet there is still something to be desired, works that still cost more than an extra working day;):

• For the attractiveness of the whole, each chapter should start with a functional image;

• Concepts that are now not explained further should end up in a glossary;

• Concrete manufacturing machines used during the course (brand, type, characteristics) are now not mentioned; It would be good to add a standardized datasheet from that.

Tags: Artificial Intelligence, 3D printing, Prompts, MindManager, PPE, Safety, Microsoft, Copilot