Metal fabrication is a process of cutting, bending, and assembling metal parts to create a final product. In the automobile industry, metal fabrication is used extensively to create the various components and structures that make up a vehicle. Steel is the most commonly used metal in the industry due to its strength, durability, and affordability. Steel fabricators play a crucial role in the automobile industry by providing customized and high-quality metal components. Here are some ways metal fabrication is used in the automobile industry with a focus on steel fabricators.

Body Panels

The body of a car is made up of numerous panels that need to be fabricated precisely to ensure proper fit and alignment. Steel fabricators use advanced technologies such as laser cutting, CNC machining, and robotic welding to create accurate and consistent body panels. Steel is also a preferred material for body panels due to its high strength, which can protect passengers in the event of an accident.

Frame and Chassis

The frame and chassis of a vehicle provide structural support and rigidity. They need to be strong enough to withstand the weight of the car and the stress of driving on rough roads. Steel fabricators use various techniques such as roll bending and welding to create sturdy and durable frames and chassis. Steel is a preferred material due to its high tensile strength and ability to absorb impact energy.

Suspension Components

The suspension system of a car is responsible for providing a smooth and comfortable ride. It consists of various components such as shock absorbers, springs, and control arms. Steel fabricators create these components using specialized fabrication techniques such as stamping and forming. Steel is a preferred material for suspension components due to its ability to absorb vibrations and resist fatigue.

Exhaust Systems

The exhaust system of a car is responsible for routing exhaust gases away from the engine and reducing noise pollution. It consists of various components such as mufflers, pipes, and catalytic converters. Steel fabricators use precision welding techniques to create customized exhaust systems that meet the specific requirements of each vehicle. Steel is a preferred material for exhaust systems due to its high heat resistance and durability.

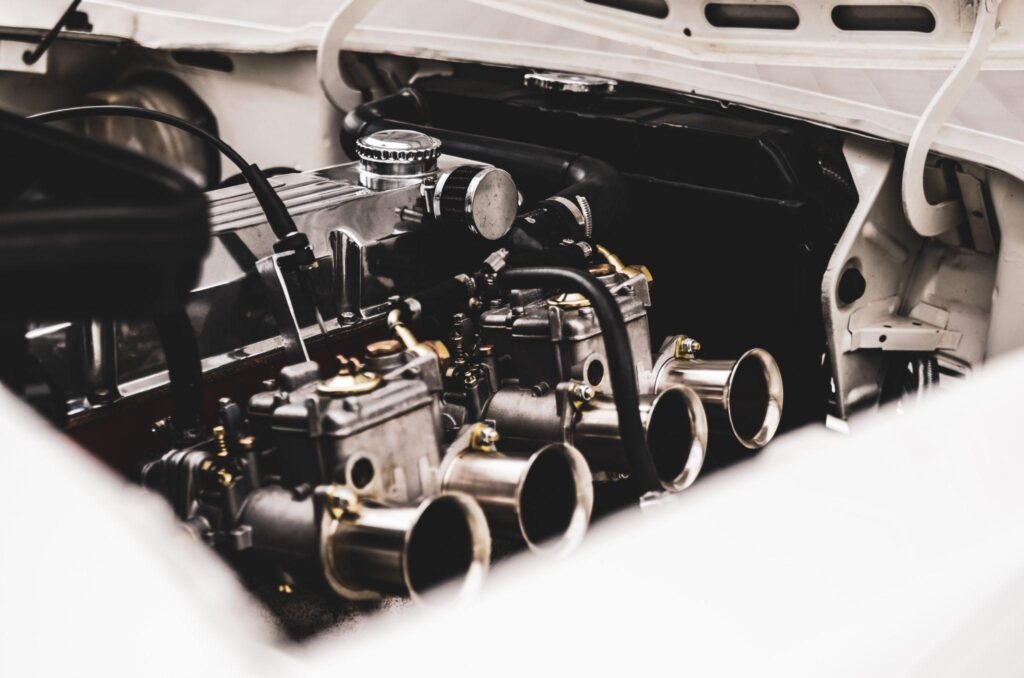

Engine Components

The engine of a car is the heart of the vehicle, and it requires numerous components to function properly. Steel fabricators create engine components such as engine blocks, cylinder heads, and connecting rods using advanced machining and fabrication techniques. Steel is a preferred material for engine components due to its high strength, heat resistance, and ability to maintain dimensional stability under extreme conditions.

In conclusion, metal fabrication plays a crucial role in the automobile industry by providing customized and high-quality metal components. Steel fabricators are an essential part of the industry by using advanced technologies and specialized techniques to create precise and durable components. From body panels to engine components, steel fabricators contribute to the safety, performance, and reliability of vehicles. The use of steel in metal fabrication ensures that the components are strong enough to withstand the stress and rigors of daily use. With the growing demand for safe and reliable vehicles, the role of steel fabricators in the automobile industry is more critical than ever.