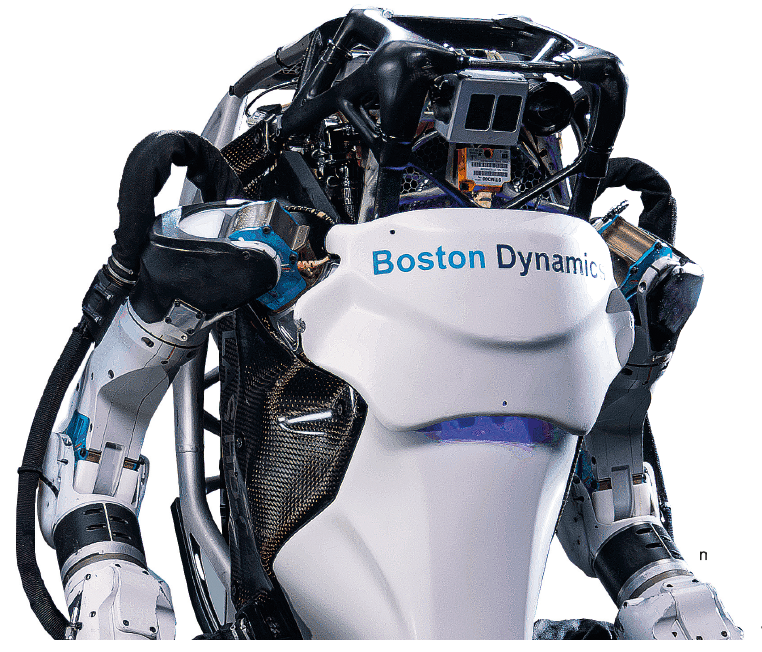

Boston Dynamics suddenly became a big name in the world of robotics when it introduced its humanoid robot Atlas in 2013. The company’s philosophy is to let robots do dangerous or physically demanding work. They are also much more accurate when taking measurements and do it completely autonomously. In this way, the robotics giant is gradually conquering the factory floor.

Marijn Ceulemans

Boston Dynamics was founded in 1992 by Marc Raibert, a former professor at the Massachusetts Institute of Technology (MIT). The company’s goal from the start was to develop advanced robotics for the business world. Robots have been populating factory floors for decades, but they are often programmed to perform a single task (often a simple action) and are also maintenance-intensive. In addition, they usually require supervision by a human worker, because if something suddenly goes wrong, the financial damage to a production line can be high.

|

The early years: BigDog and RHex

In its early stages, Boston Dynamics focused primarily on research and development, with the goal of developing new technologies that could improve the mobility and autonomy of robots. Over the years, Boston Dynamics has partnered with governments and private organizations to test and improve its robots. The company has signed contracts with the U.S. military, DARPA, and NASA, as well as several other companies and research institutions. These partnerships have led to the development of advanced robots with a wide range of applications, including surveillance, explosive ordnance disposal, logistics, medical applications, and more. The company’s first major success came in 2005 with the development of BigDog, a four-legged robot designed to carry heavy loads. BigDog used dynamic stabilization to balance itself, allowing it to walk over rough terrain and act as a mule. This made it ideal for military applications, such as carrying equipment, ammunition, and other supplies for soldiers. BigDog was equipped with an advanced system of hydraulic actuators, sensors and a CPU to balance and navigate itself. The robot had four legs with a motor on each leg, allowing it to move smoothly over various terrains. BigDog was able to walk, run and even jump, which not only gave it a lot of carrying capacity, but also made it very mobile. The prototype of BigDog was first tested in 2005 and it certainly did not go smoothly. The robot suffered from technical problems, such as overheating and sometimes lacked stability. Nevertheless, the project continued and several improvements were made. In 2007, Boston Dynamics unveiled a new prototype of BigDog, which featured several significant improvements over the original model. The new prototype was faster, stronger and better able to walk over inhospitable terrain. After the success of BigDog, Boston Dynamics went on to develop more robots, including RHex, a 6-legged robot that was also designed for terrain exploration and performing tasks in difficult to reach areas. He could quickly adapt to different environments, making him ideally suited for search and rescue operations.

|

|

When it comes to raw speed, Cheetah is the robot to beat. |

Cheetah: The Fast Robot

Slightly less well-known, but no less ingenious, is Cheetah, a four-legged robot that Boston Dynamics unveiled in 2012. Unlike Spot, it was designed to run at high speeds. It reached a maximum speed of 45 km/h and could also adapt to the terrain. Over time, Boston Dynamics has given Cheetah several upgrades, including new sensors and cameras, improved algorithms for object recognition and navigation, and improved hardware and software. Cheetah has been used for patrolling difficult terrain, surveillance in border areas, and delivering packages, among other things.

|

|

Atlas’ movement capabilities are downright impressive. |

Atlas: the walking robot

If you’ve been following the tech news for the past few years, you’ve probably come across a YouTube video of Boston Dynamics demonstrating Atlas, its first humanoid robot. Following in the footsteps of BigDog and RHex, it was originally designed for navigation and disaster recovery, but Atlas also showed great potential for repetitive tasks in industrial and logistics environments, such as moving heavy boxes or factory parts around a warehouse. Equipped with balance sensors, it can walk upright like a human. It’s also equipped with sensors and cameras that allow it to recognize objects and make navigation decisions. Atlas’ mobility is astonishing, as evidenced by the many videos on Boston Dynamics’ YouTube channel (highly recommended). In the video clip “Atlas Gets a Grip” from about a year ago, you can see it assisting a construction worker by handing him his bag of tools, then doing a somersault. Just because it can.

The first version of Atlas was unveiled in 2013, which suddenly gave Boston Dynamics a lot of attention online, because what Atlas could do had never been shown before. The robot could walk, run and even jump. This allowed Atlas to overcome obstacles and adapt to different environments. Over the years, Boston Dynamics has made several improvements to Atlas. For example, it added new sensors and cameras and improved the algorithms for object recognition and navigation. The hardware and software of the robot have also been refined over the years. The first versions of Atlas had to rely on wired power supply, while the latest versions have an internal battery. A major upgrade was the renewed Atlas from 2016. Its arms and legs were redesigned, allowing it to walk and run better. The robot was also equipped with new sensors and cameras, making it even better able to recognize objects and navigate through spaces independently. Over the years, Atlas has been used for rescue operations in disaster areas, where it was able to locate and evacuate people. He has since been successfully employed in factories and warehouses to operate machinery, assemble and move parts. The latest version of Atlas is 1.50 m tall, weighs 89 kg and can run up to 9 km/h. He can clamp objects weighing up to 14 kg between his arms and with the new

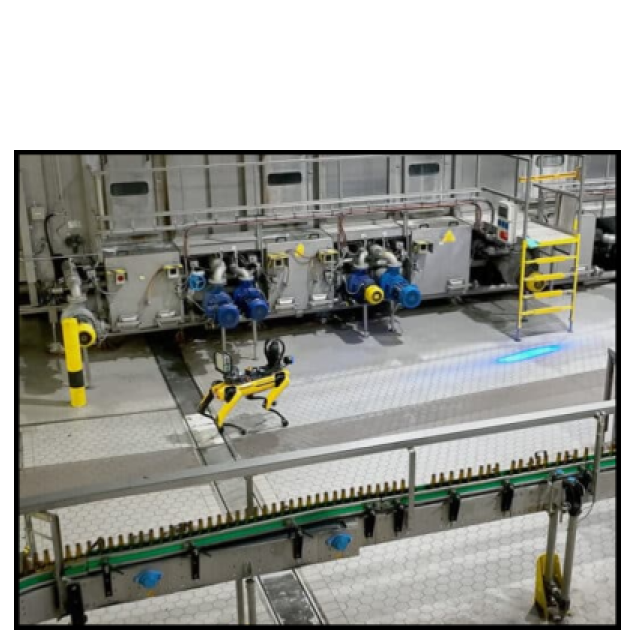

Robot dog spotted in BelgiumSpot, the robot dog from Boston Dynamics, started working at the AB InBev brewery in Leuven in January of this year. There he inspected packaging lines (fully autonomously) for technical issues. As part of the Brewery of the Future program, Spot performed 1,800 individual inspections per week on 10 packaging lines that deliver 50,000 cans and bottles of Stella Artois, Budweiser and Corona per hour. In his first six months in Leuven, Spot detected almost 150 technical errors. The average time that technicians had to spend on repairs was reduced from a few months to 13 days. “We ourselves can only hear problems when we stop the production line. But with Spot’s inspection, production no longer has to be interrupted. In addition, we can detect technical issues before they cause problems,” says the Strategic Projects Acceleration Manager. |

‘Robot Dog’ Spot

Perhaps even better known than Atlas is the bright yellow robot dog Spot. It was unveiled in 2015 and also regularly appears in funny YouTube videos. Make no mistake: it also does a lot of work these days and has already proven to be very useful. For example, in January of this year it was released into the Stella Artois brewery in Leuven for technical inspections (see box). Spot is designed to navigate through tight spaces. Boston Dynamics provided a gripper on its back, but that module can just as easily be replaced by custom-made equipment, such as infrared sensors and special cameras. It all depends on the needs of the customer. This makes Spot multi-deployable in, among other things, (agricultural) construction and along production lines in factories. The robot has also been used to inspect wind turbines, where it was able to check the condition of the turbine blades and detect defects. Spot can also inspect pipelines, checking the condition of the pipes and detecting leaks before they become a problem.

|

| The bright yellow robot dog Spot is a master at inspecting technical installations. |

Over the years, Boston Dynamics has made several improvements to Spot, including adding new sensors and cameras, improving the object recognition and navigation algorithms, and refining the robot’s hardware and software. These improvements have further improved Spot’s performance and expanded its capabilities. Spot is one of the most advanced robots ever created, and it has demonstrated that robots can perform complex tasks in difficult environments.

Music of the future

The advanced versions of Atlas and Spot are just the beginning for Boston Dynamics. The tech company is working on developing robots that can operate autonomously, not just in cities and factories, but also in hospitals, for example. Boston Dynamics is working on developing robots that are able to collaborate with humans, sharing tasks and performing complex manipulative tasks in manufacturing environments. These robots will be able to work with humans to assemble products and operate machinery. Boston Dynamics has already worked with several hospitals and other medical institutions to develop robots that can assist in caring for patients and performing medical procedures. With its advanced technologies and unprecedented mobility, Boston Dynamics has already had a major impact on society. They have a key role to play in shaping the future of robotics and the way robots are used to continue to modernize our economy.