When Honda launched the Dual Clutch Transmission fifteen years ago, that semi-automatic transmission with quite a bit of skepticism was received, but now Yamaha, KTM and BMW have launched similar transmissions. The next in line might be Ducati that patent requests for semi-automatic transmissions has submitted.

A series of patent applications submitted by Ducati shows that the development department in Borgo Panigale is working on a fully automatic or semi-automatic gearbox, with a system that automates the operation of the clutch and leaves it to the driver to change acceleration in the conventional manner.

That is of course not the first time. MV Agusta’s SCS (Smart Clutch System) combines a ramp of centrifugal coupling with a quickshifter to relieve the left hand of the rider, while Honda’s more recent e-clutch system adds an actuator and computer control to a further conventional coupling, which means that the operation is the operation of the coupling as you take the coupling overt about the coupling. does it yourself.

Ducati’s system is closer to the Honda E-Clutch than with the SCS of MV Agusta. Just like the Honda Design, the use of a computer control unit and an electromechanical actuator to work parallel to the conventional clutch lever, so that you can choose between manual or automatic and always the system manually override. In contrast to Honda’s cable bed design, that of Ducati is hydraulic.

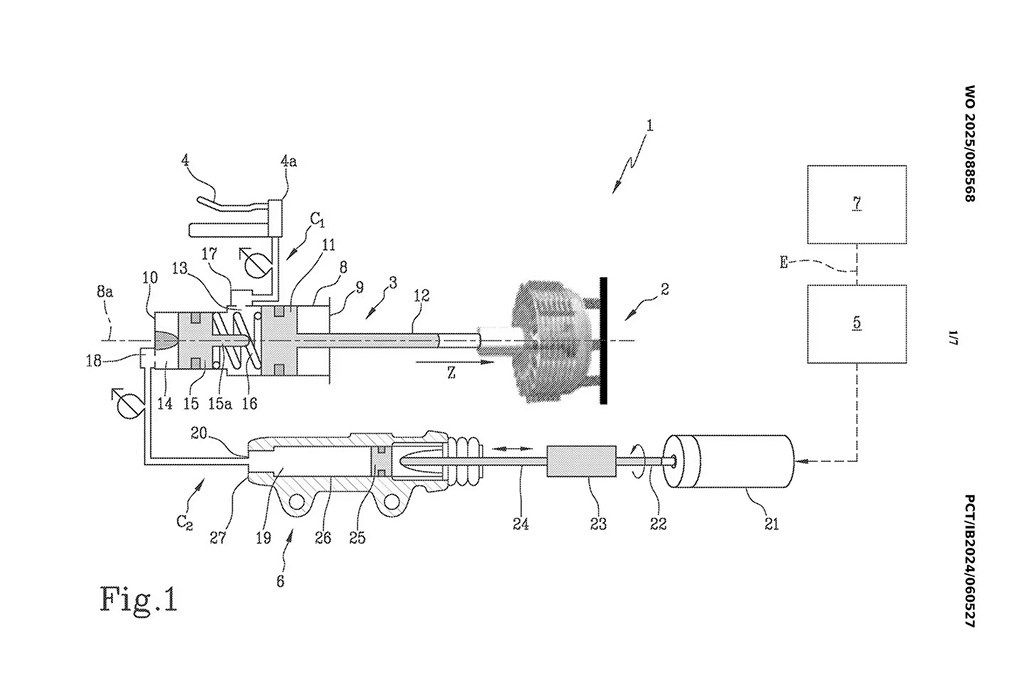

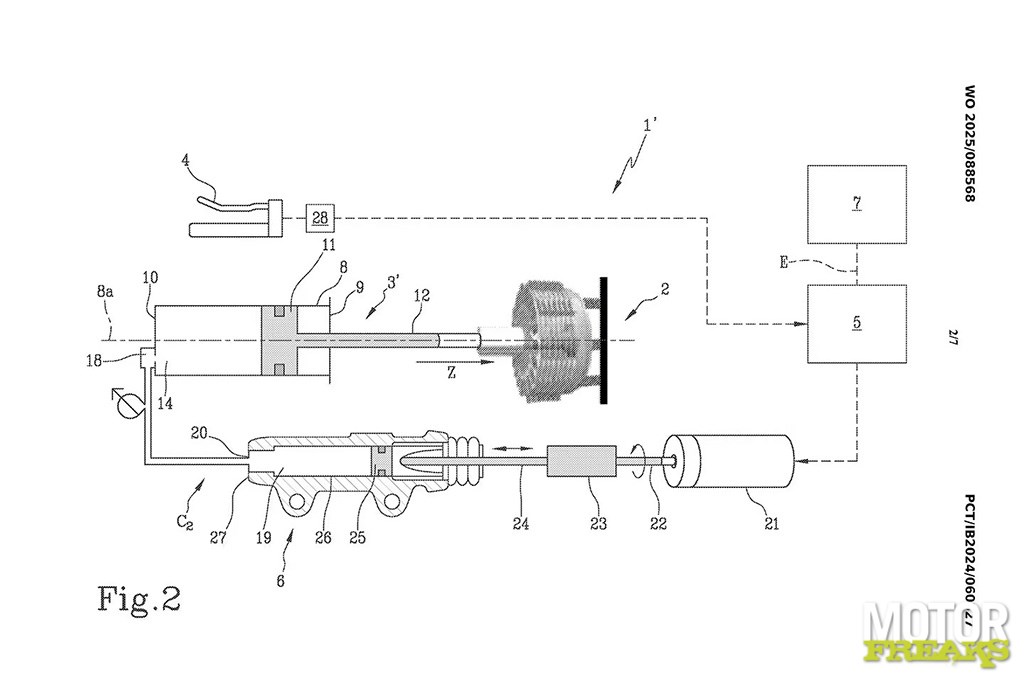

There are two variants of the system explained in Ducati’s patent applications. Both variants work identically in terms of the rider, but take a different route to the same goal. The simplest version is designed to be easily built into existing engines with hydraulic couplings and consists of four main components.

There is a computer control unit that operates the system and is connected to an electromechanical actuator, which is in fact an electric motor that runs a wire rod in a spindle, which in turn moves the wire rod up and down, depending on the direction in which the engine turns. This in turn operates a pressure rod in a hydraulic head coupling pump. These parts are present on both versions of the Ducati design.

The difference between the two systems is in the manual control of the coupling. In the first version, the decoupling unit (9) is operated hydraulically via the clutch lever (9), with the second version an electronic signal is sent to the computer control unit via the coupling lever.

Both versions offer the same benefits as Honda’s E-Clutch. You do not have to use the clutch lever at all if you prefer not to do so, because the electronics automatically disconnect the clutch when you come to a halt and switch on when you give gas again. But you can also use the coupling manually, whereby the system acts as a safety net and prevents the engine from turning down.

Ducati has also provided the system with Launch Control, whereby the disconnection is therefore electronic. And finally, there is a switching strategy for the system, which cooperates with a load sensor in the foot-operated switching mechanism to properly switch the clutch on and off while switching back and off, while the engine management ensures automatic flips.

In the applications, Ducati points out that the system is specially designed for racing engines and high performance engines, and that it offers a speed and precision level that cannot reach competitive designs. By building in the system in a production engine, Ducati could circumvent the rules that prohibit automatic couplings in the WorldSBK, since the technical regulations of the FIM states: “No power source (ie hydraulic or electric) may be used to operate the coupling.” “Unless it is approved in the production model,” Ducati could then state.

– Thanks for information from Motorfreaks.