The aim is to develop sensitive ‘artificial skins’ – for example for prosthetics – that can feel comparable – if not better – than our real fingers.

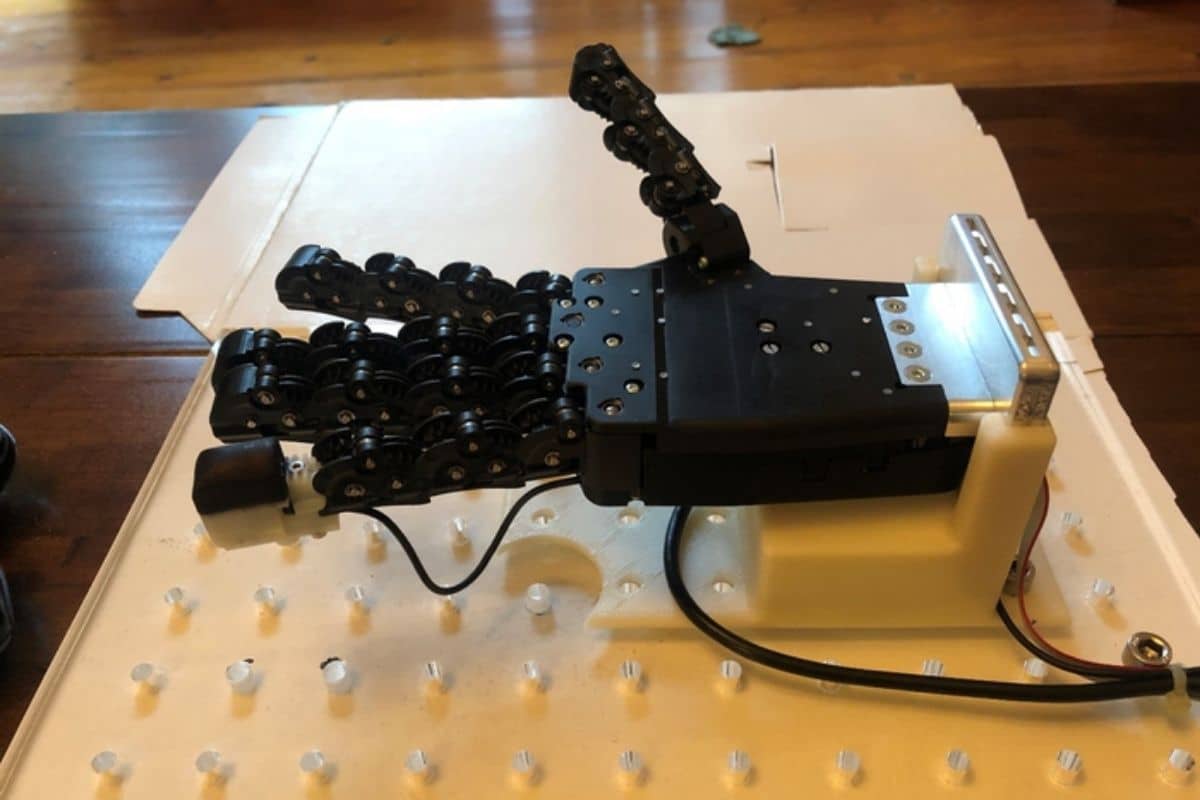

Developments in the field of robotics are moving fast. In the meantime, robots have already been created that can fly, swim and dive, and even ones that can reproduce themselves – without human intervention. It all sounds very clever. At the same time, researcher Nathan Lepora is also critical. “The agility of robots is just a pale imitation of that of humans,” he says in conversation with Scientias.nl† But with the development of a particularly sensitive 3D-printed fingertip, he is taking important steps forward.

sense of touch

While computers have been beating the best chess players in the world for decades, robots cannot move a simple chess piece the same way we do. This is mainly due to the sensitivity of our fingertips. “Scientists know that the human sense of touch is essential for our physical dexterity,” Lepora said. “It allows us to perform common household tasks, as well as build advanced tools and instruments.” However, this human characteristic is not yet so easy to imitate in robotics. “Many different technologies for a robotic sense of touch have already been proposed,” says Lepora. “But none came as close to reality as ours.”

3D printed fingertip

In the new study Lepora and his colleagues succeeded in giving a 3D-printed finger sense of touch. Our own sense of touch is created by various specialized bodies and nerve endings in or just under the skin. To mimic this, the researchers used a 3D-printed skin with a few ‘pins’ on it. “These look like hundreds of tiny pins pointing inwards,” Lepora explains. “They replicate a similar structure in human tactile skin, namely the dermal papillae.”

Cross section of the 3D printed fingertip. The white plastic acts as a kind of holder for the flexible black rubber skin. Both parts are manufactured together on an advanced 3D printer. The ‘pins’ on the inside of the skin replicate skin papillae from human skin. Image: Prof. dr. Nathan Lepora

The 3D-printed fingertip turned out to be able to ‘feel’ like a human fingertip. “We found that our 3D-printed fingertip can produce artificial nerve signals similar to those produced by real, tactile neurons,” Lepora said.

Applications

The fact that researchers have now succeeded in mimicking the human sense of touch in robotics opens the door to many new possibilities. “In principle, a robotic hand with the dexterity of the human hand could do all the physical chores and chores that we do; from washing dishes to sorting waste for recycling,” says Lepora. “There is currently a huge demand from the logistics and food industry for robots that can automatically pack goods, for example. Much of this is still done by humans today, because robots lack the dexterity needed.”

prostheses

Not only can robotic hands take over chores or tasks with the sense of touch, it also holds great promise for the development of increasingly better prosthetics that can feel just as good – if not better – than real fingers. “3D printing tactile skin could lead to robots that are not only more convenient, but also significantly improve the performance of prosthetic hands by giving them a built-in sense of touch,” said Lepora.

With their study, the researchers have taken an important step towards optimizing the agility of robotics. “I’m very proud that our 3D-printed fingertip is very similar to a real fingertip,” says Lepora. “40 years ago, scientists measured nerve signals while pressing a fingertip against ridges and ridges. We now found a similar pattern of artificial neural activity in our 3D-printed skin.”

Improvement point

Despite this important step, we are not there yet. “One point for improvement is that our 3D-printed skin is not very sensitive to fine details, like a human finger is,” continues Lepora. According to Lepora, this can be explained by the fact that the 3D-printed skin is thicker than the real skin. “We could feel spaces between ridges of about 1 to 2 millimeters, while humans feel spaces less than a millimeter,” he continues. “We therefore want to further improve our design so that it becomes just as sensitive – or even more sensitive – than human skin.” The team is now investigating how finer structures can be 3D printed, comparable to the microscopic scale of human skin.

Human touch

An interesting question is whether the human sense of touch is actually the most optimal way to manufacture more agile robots. “There is indeed an ongoing debate about whether artificial sense of touch should mimic our own sense of touch,” says Lepora. “But I do see that as a good starting point. In my opinion, the use of our hands is a defining characteristic of being human. Our distant ancestors already built tools that they made with their own hands. All modern technology comes directly from machines that were originally hand-crafted. In addition, all of humans’ tricks and gimmicks are rooted in our cognitive abilities, allowing us to design tools that help us achieve desired plans and goals.”

Although there is still a long way to go before 3D-printed tactile fingertips will be used in everyday life, Lepora’s study shows that it is possible. “The most exciting moment for me was when we looked at our artificial nerve images from the 3D-printed fingertip and they resembled the real images taken more than 40 years ago,” he says. “We’ve been working on our design for ten years, based on recreating the physical structure of human skin. And we now show that our artificial signals are very similar to real nerve signals. This shows that we have succeeded in mimicking the way human tactile skin functions.”

Source material:

†Touchy subject: 3D printed fingertip ‘feels’ like human skin” – University of Bristol

Interview with Nathan Lepora

Image at the top of this article: Prof. dr. Nathan Lepora